When a lot of people hear “print,” they think paper. If they don’t, they at least might think about flat surfaces like T-shirts or bags. But take a few laps around the PRINTING United Expo, the global print industry trade show being held Sept. 10-12 in Las Vegas, and you’ll see just how much technology is dedicated to printing on all sorts of rounded substrates – especially drinkware items. Drinkware has a sizeable footprint on the show floor, from the direct-to-film printers showing graphics on water bottles and sublimated pieces like mugs to direct-to-object printing on items like pint glasses and wine bottles.

Checking out the offerings can certainly inspire distributors who include drinkware products in their orders while also generating ideas for print-first distributors about how to harness the power of a promotional hard good to kit along with other products.

With that in mind, here are several trends in the drinkware category that end-users are looking for, as well as decoration techniques that can elevate a distributor’s branded products campaign.

Go Big

The 40-oz. Stanley Quencher (or “Stanley Cup” as it’s colloquially known) is still probably the “it” drinkware item. Other challengers have entered the arena, like the Owala brand carried by ETS Express (asi/51197), but the king-sized influence of Stanley still looms large.

Indeed, “big” was a theme throughout drinkware selections at the expo. For instance, there were slightly larger versions of traditional items, like camper mugs with straws and classic to-go thermoses.

Relatedly, some drinkware items now have their own accessories, such as small pouches, which were on display at Counselor Top 40 supplier alphabroder’s (asi/34063) booth.

The accessories make practical sense: After all, if the tumbler isn’t going to fit in some small bags, it might as well carry its own weight by holding an ID or a credit card. Plus, that additional bag allows for even more imprint space for your customer.

The Power of a Label

For items like bottles or growlers that might be sold to wineries, breweries or distilleries, good labels are a key to branding.

In a presentation on the growing label market, Cory Francer, an analyst with PRINTING United Alliance’s NAPCO Research, reported that U.S. demand for labels is expected to reach $20.6 billion by 2025, with 3.3% annual growth per year.

Distributors and decorators can play with different textures, colors and inks to turn what could be a bland, forgettable label into something that catches an end-buyer’s eye on a drinkware item.

In addition to labels printed onto adhesive paper, printers were exhibiting their capabilities for 360-degree label printing with tactile characteristics and no visible “seam.”

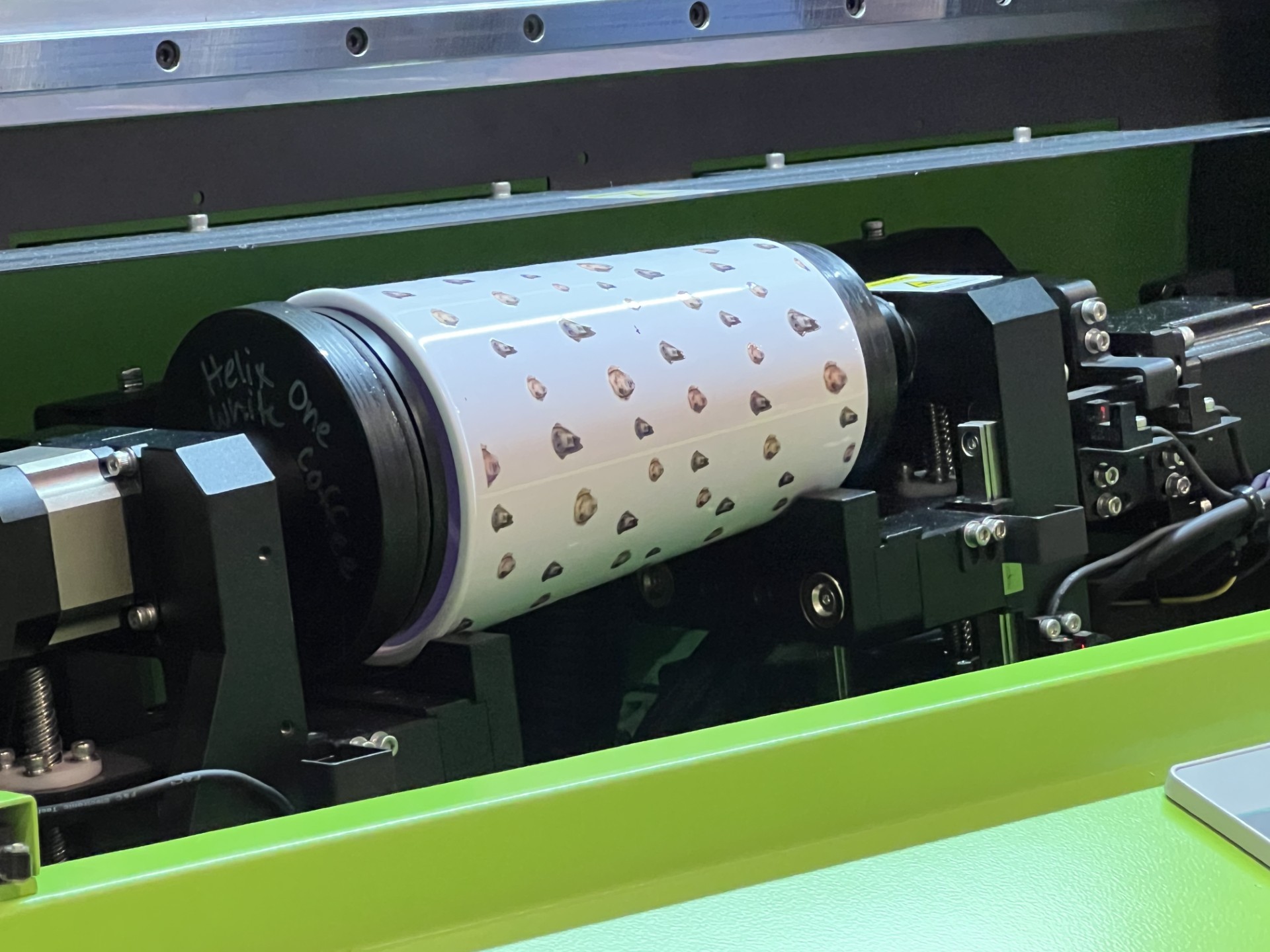

To that point: Printers were on hand to demonstrate how direct-to-object UV printing can take a drinkware item like a tumbler or pint glass and create an all-around branding experience by printing designs top to bottom in seconds.

Inkcups was demonstrating its new Double Helix printer, which uses a Nano Pin Curing technology, allowing for printers to decorate objects without the need to stuff them with material to prevent curing the print head.

“When you’re printing on clear vessels, up until now you really had to stuff these either with a fox tail – which looks like a Swiffer duster-type object – or if it has a long skinny neck, the guys fill it with little beads because it will cure the print head with a clear vessel,” explained Riley Mann, digital marketing strategist for Inkcups. “With the Nano Pin Curing technology, we’re protecting the heads, so it’s a much more streamlined process for printing.”

Mann also demonstrated the Helix ONE printer, which is the company’s benchtop cylindrical printer, used for items like tumblers. It serves as the entry-level printer of this type for decorators looking to expand their drinkware printing capabilities without breaking the bank or taking up too much physical real estate while still churning out pieces in about 60 seconds with full CYMK varnish.